The groundbreaking nano-printing technology from the University of South Bohemia has attracted the scientific world

Scientists from the Faculty of Science at the University of South Bohemia and the Czech Academy of Sciences have developed a groundbreaking method that enables the printing of structures combining nanoparticles and sintered metal using laser printing. This technology opens doors to new possibilities in electronics, optics, and medicine. Imagine a custom-made implant that contains printed conductors and sensors.

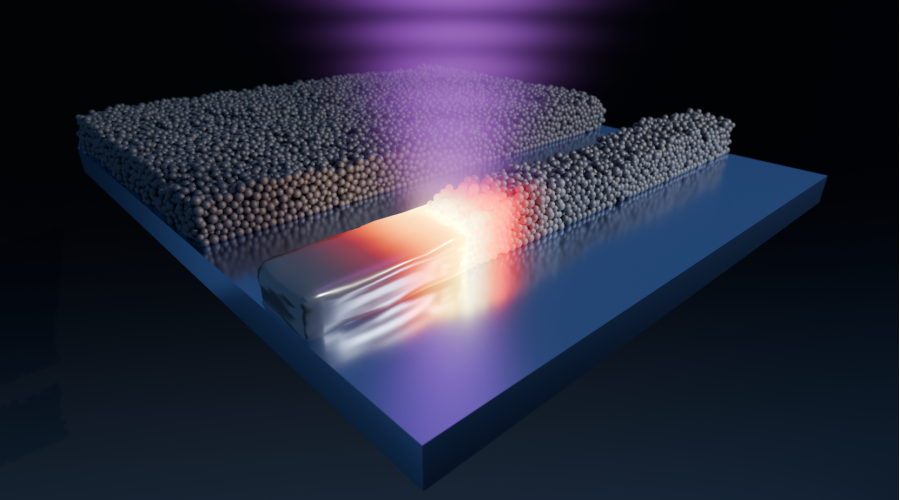

How does it work? The key is to create a beam of nanoparticles, objects that are 1,000 times smaller than the thickness of a human hair. Then, a substrate is placed in the nanoparticle beam and irradiated with a laser programmed for the desired structure. This method leverages nanoscale properties of matter, such as a fivefold lower temperature required for particle sintering and the easy evaporation of material, allowing the print resolution to be limited only by the wavelength of light, not particle size.

This innovative approach has enabled the production of micro-mirrors, micro-wires made of nanoparticles and sintered metal, and even the logo of the Technology Agency of the Czech Republic thanks for their support. Scientists hope this method will revolutionize sensor manufacturing and flexible electronics, especially in medicine.

The new technology was developed in collaboration between the Department of Physics and the Department of Chemistry at the Faculty of Science, University of South Bohemia, and the Biology Center of the Czech Academy of Sciences. Technology was patented and published in the prestigious journal Nano Letters from the American Chemical Society, and the editorial team selected it for the front cover of the issue.

"Obtaining the patent is essential for us. It shows not only that we came up with something completely new at a time of boom in additive manufacturing, but it also opens doors for applications in practice, which we are currently exploring in cooperation with the Technology Transfer Office at the University of South Bohemia. The selection as the front cover of Nano Letters journal demonstrates that our technology, on which the team has worked for three years, is of international importance and that we are pursuing an exciting research path, even though it wasn’t always easy," says physicist Jiří Kratochvíl, the team leader.

The method also made it to the finals of the Czech national technology competition Transfera.

Link to publication HERE.

Extended version on the Faculty of Science website HERE.

Figure captions:

- Laser printing from gas-aggregated nanoparticles enables the fabrication of microstructures combining nanoparticles and sintered metal. Nanoparticles are homogeneously deposited on the substrate and form a thin film. The laser at high power ablates the material around the structure being fabricated; meanwhile, the laser at low power sinters nanoparticles into continuous metal film.

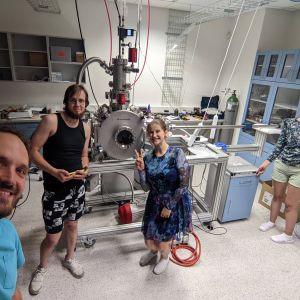

- The research group of Jiří Kratochvíl with the device for nanoparticle production used for laser printing that was developed and assembled by the team at the Department of Physics, Faculty of Science, University of South Bohemia. From left to right: Jiří Kratochvíl, Oleksandr Mashchenko, whose dissertation focuses on laser printing from nanoparticles, Yasmina Al-Muhkhrabi, and Tereza Patlejchová.

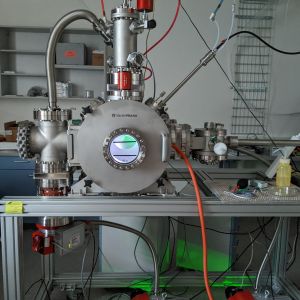

- Detail of the deposition system, showing low-temperature plasma in the window. In addition to nanoparticle printing, the device can be used to prepare functional materials that incorporate nanoparticles embedded in a thin layer, such as antibacterial or antiviral coatings.